Urban industrialization has significantly contributed to the decline in air quality over the years. In the modern world, air quality has become a major concern, particularly in urban areas with consistently high pollution levels. Innovative air filters were developed as a transformative solution to this serious problem.

These advanced filtration systems are designed to combat the limitations of traditional filters, which often struggle with clogging and inadequate removal of harmful particulate matter and pollutants. By incorporating cutting-edge materials and technologies, innovative air filters enhance efficiency, longevity, and overall performance.

They are capable of capturing finer particles and a wider range of contaminants, ensuring cleaner air intake for various applications, from automobiles to industrial systems. This not only improves the operational efficiency of machinery but also contributes significantly to environmental health and human well-being.

Signicent is actively contributing to a cleaner future by assisting its clients by providing technology intelligence solutions to develop innovative air filters, effectively addressing today’s air quality challenges.

Challenges:

Conventional air filters, while promising, face several real-life challenges:

- Despite normal designs, these filters require regular maintenance and eventual replacement. Neglecting these needs can reduce efficacy and damage machinery.

- Air filters need to prove their effectiveness in a wide range of environmental conditions. Variations in humidity, temperature, and pollution levels can affect their performance, and ensuring consistent efficacy across different scenarios remains a challenge, especially in diverse industrial settings.

- Automotive Air Filtration poses challenges in particle size filtration and airflow optimization to maintain engine efficiency and prevent cabin air contamination.

- HVAC System Filtration faces challenges in maintaining air quality, controlling moisture levels, and ensuring timely filter replacement for efficient operation and indoor air cleanliness.

Challenges Related to Industrial Furnace Flue Gas Filtration:

- Traditional filter materials may not withstand the high temperatures of flue gas, necessitating the development of heat-resistant materials to maintain filtration efficiency.

- Corrosive gases in the flue gas can cause filter materials to degrade rapidly, leading to reduced filter performance and increased maintenance requirements.

- Ensuring the durability of filter materials under harsh conditions is essential to avoid frequent replacements and associated downtime, emphasizing the need for robust and long-lasting filtration solutions.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Innovative Solutions for Air Filters:

To address the aforementioned challenges, the manufacturers have started developing self-monitoring systems with in the filters that alert users when maintenance or replacement is required

- Using materials such as ceramic composites or graphene-based filters can significantly improve the longevity and robustness of air filters.

- Advanced Filtration Technology: Research and development in nanotechnology has led to the development of filters with enhanced particle capture efficiency and reduced airflow restriction, improving engine performance and cabin air quality.

- Optimized Airflow Design: Computational fluid dynamics (CFD) simulations and advanced airflow modeling techniques have helped in designing filters that optimize airflow while effectively trapping particles.

- Smart Filtration Systems: Implementing IoT-enabled smart filtration systems can automatically monitor air quality, moisture levels, and filter status. This allows for proactive maintenance scheduling and ensures optimal indoor air quality with minimal energy consumption.

- Advanced Moisture Control Mechanisms: Utilizing innovative humidity sensors can effectively manage moisture levels within HVAC systems, preventing mold and bacteria growth and maintaining a healthy indoor environment.

- Development of Heat-Resistant Materials: Heat-resistant filter materials, such as ceramic fibers or metal alloys are capable of withstanding high temperatures of industrial furnace flue gases.

- Corrosion-Resistant Coatings: Corrosion-Resistant Coatings: Applying specialized coatings or surface treatments to filter materials, such as stainless steel, aluminum, and titanium, can enhance their corrosion resistance, prolonging their lifespan and maintaining filtration efficiency in corrosive environments.

Through comprehensive Technology gap analysis, we can identify areas where our clients can improve their competitive edge and capitalize on emerging opportunities.

Market research:

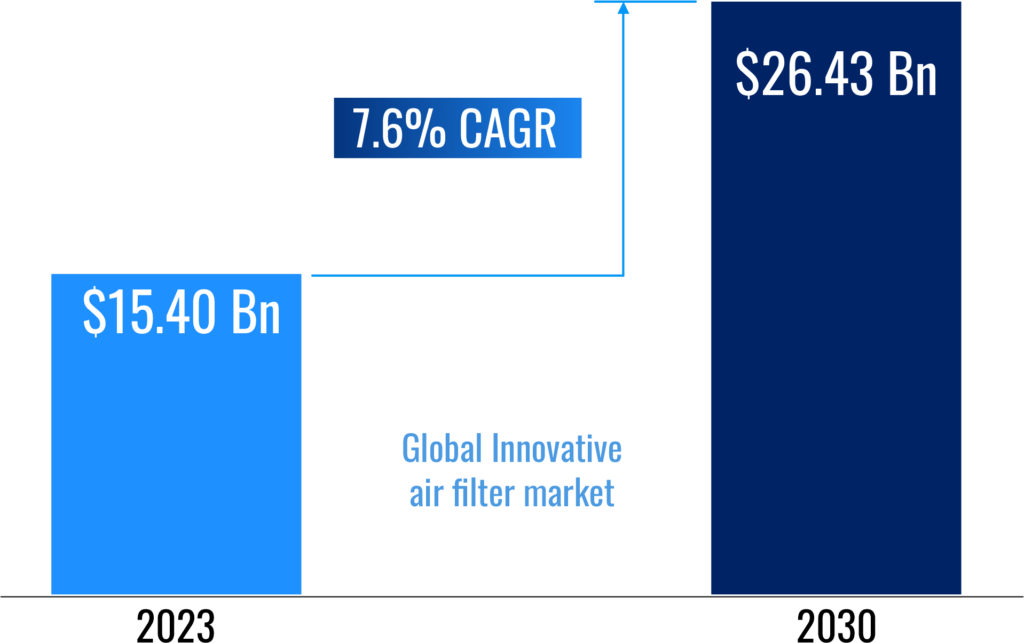

As per Signicent’s Market Researchers, the global Air filters market is likely to reach values in the ranges shown below.

Key players:

Here are the leading key players in the innovative air filter industry:

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Technology Intelligence

- Market Research

- Patent Landscape

- Technology gap analysis

- Design Patent Search

- Portfolio Analysis

- Freedom to operate

- Bio Sequence Search

- Innovation pipeline identification

- Chemical Structure Search

- Patent Invalidity Search

- Manufacturers Search/ Supplier search

- Patent Licensing Services

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.