Hydrogen fuel production technologies have played a crucial role in the global shift towards sustainable energy solutions. Key methods include Steam Methane Reforming (SMR), electrolysis, and biomass gasification, each offering unique advantages and challenges. SMR, reliant on natural gas, emits CO2, posing environmental concerns. Electrolysis, powered by renewable energy, offers a cleaner alternative but faces cost barriers. Biomass gasification leverages organic waste for sustainable hydrogen production. As innovations progressed, cost reductions made hydrogen fuel increasingly viable for widespread adoption.

Over the past decade, hydrogen production has made significant strides in reaching commercial viability. Advancements in technology and increased investment have driven down costs and improved efficiency across all major production methods. Governments worldwide are implementing policies and incentives to foster hydrogen infrastructure, further accelerating market integration. The development of large-scale hydrogen projects and partnerships between public and private sectors have showcased the potential of hydrogen as a cornerstone of the future energy landscape. Hydrogen’s role in decarbonizing industries, powering fuel cells, and providing energy storage solutions underscores its critical importance in the transition to a sustainable energy system.

Signicent is actively contributing to the hydrogen sector by leveraging state-of-the-art technologies and market research reports to enhance production and deliver sustainable and client-focused energy solutions.

Challenges:

- The availability and cost of renewable energy sources (such as solar and wind) to power electrolysis processes for hydrogen production. Dependence on fossil fuels could undermine the environmental benefits of hydrogen as a clean energy source.

- Improving the efficiency and scalability of electrolysis technologies is crucial. This includes developing advanced catalysts, optimizing process design, and reducing energy consumption per unit of hydrogen produced.

- Scaling up hydrogen production facilities is essential to achieve lower unit costs through increased production volumes and operational efficiencies. This requires significant investment in infrastructure and coordination among stakeholders to build a robust hydrogen supply chain.

- Establishing a comprehensive hydrogen infrastructure, including production plants, storage facilities, and distribution networks, required substantial investment. Lack of infrastructure could limit the accessibility and utilization of hydrogen as an energy carrier.

These challenges represented critical areas where innovation, investment, and supportive policies could drive progress towards cost-effective hydrogen production and widespread adoption as a sustainable energy solution.

Innovations:

Increasing the use of renewable energy sources such as solar and wind to power electrolysis processes.

- Research at institutions like the National Renewable Energy Laboratory (NREL) in the USA focused on integrating solar PV with electrolysis systems to directly produce hydrogen from sunlight. Advanced wind-to-hydrogen technologies were also being developed, such as those studied at the Fraunhofer Institute for Wind Energy Systems (IWES) in Germany.

- NREL’s work on photoelectrochemical (PEC) water splitting using semiconductor materials like gallium indium phosphide (GaInP₂) aimed to improve efficiency and reduce costs by leveraging renewable electricity directly from solar panels.

Developing advanced catalysts and optimizing electrolysis processes to increase efficiency and reduce energy consumption.

- The Joint Center for Artificial Photosynthesis (JCAP) in the USA came up with molecular catalysts and materials for efficient water splitting. They explored cobalt-based catalysts and nanoscale materials to enhance reaction kinetics.

- JCAP’s development of cobalt-phosphide nanoparticles as electro catalysts showed promise in accelerating hydrogen evolution reactions, making electrolysis more energy-efficient and cost-effective.

Scaling up hydrogen production facilities to achieve cost reductions through improved manufacturing processes and bulk procurement of materials.

- The Hydrogen Technology Cluster Australia (HTCA) focused on large-scale electrolysis projects powered by renewable energy. They aimed to build integrated hydrogen hubs capable of producing green hydrogen at competitive costs.

- HTCA’s collaboration with industry partners and government support was facilitating the construction of the Western Green Energy Hub in Australia, expected to be one of the world’s largest renewable hydrogen projects.

Signicent plays a pivotal role in the renewable energy sector through proactive technology scouting and strategic insights.

These solutions highlighted ongoing efforts and advancements in hydrogen production technologies worldwide, emphasizing the importance of collaborative research, innovative approaches, and supportive policies to overcome challenges and accelerate the adoption of hydrogen as a sustainable energy solution.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Technology Trends:

Electrolysis Technologies: Advances in electrolysis technologies, including alkaline electrolysis, proton exchange membrane (PEM) electrolysis, and solid oxide electrolysis cells (SOECs), are improving efficiency and reducing costs.

Renewable Integration: Increasing integration of renewable energy sources like solar and wind with electrolysis for green hydrogen production is a key trend.

Carbon Capture and Storage (CCS): Technologies combining hydrogen production with CCS to produce blue hydrogen are gaining traction, particularly in regions with existing fossil fuel infrastructure.

Blue hydrogen is produced through a process called steam methane reforming (SMR), where natural gas (methane) undergoes a reaction with high-temperature steam to produce hydrogen (H2) and carbon monoxide (CO). The CO produced is then reacted with steam to produce additional hydrogen and carbon dioxide (CO2). The key distinction of blue hydrogen is that the carbon dioxide generated during the production process is captured and stored using carbon capture and storage (CCS) technologies to prevent its release into the atmosphere.

Signicent actively participates in advancing Technology Readiness Levels (TRLs) by evaluating and enhancing the maturity of emerging technologies

Purposes and Uses of Blue Hydrogen:

Transition Fuel: Blue hydrogen was often seen as a transitional fuel in the shift towards a low-carbon economy. It could replace traditional fossil fuels like coal and oil in industries where decarbonization was challenging, such as heavy industry and manufacturing.

Hydrogen Production: Blue hydrogen served as a clean source of hydrogen for various applications, including fuel cells used in transportation (e.g., hydrogen fuel cell vehicles), power generation, and industrial processes.

Energy Storage: Hydrogen produced through blue hydrogen processes could be stored and used as a means of energy storage, particularly in scenarios where renewable energy sources like solar and wind generated excess electricity that could be converted into hydrogen through electrolysis.

Reducing Carbon Emissions: By capturing and storing the CO2 emissions associated with hydrogen production, blue hydrogen helped reduce greenhouse gas emissions compared to traditional fossil fuels, supporting climate change mitigation efforts.

Signicent contributes to this aim by using technology monitoring and market insights to identify the latest advancements

Market search:

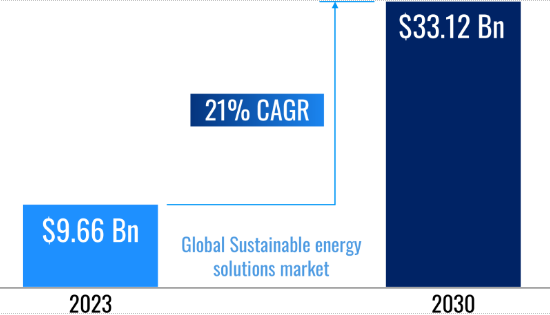

As per Signicent’s Market Intelligence, the global market for sustainable energy solutions is likely to reach values in the ranges shown below.

Industrial Applications:

Blue hydrogen was used in industries requiring high-energy-density fuels or feedstocks, such as refining, ammonia production, and chemical manufacturing.

Overall, blue hydrogen played a crucial role in reducing carbon emissions while maintaining energy security and supporting the integration of renewable energy sources into the energy mix. Its development and deployment were seen as part of a broader strategy to achieve sustainable and environmentally responsible energy solutions.

The companies mentioned belong primarily to the field of hydrogen production and its applications in sustainable energy solutions, specifically focusing on blue hydrogen initiatives. Here’s how they align with different sectors:

Air Products and Chemicals, Inc. and Linde plc: These companies were leaders in industrial gases and engineering, heavily involved in hydrogen production technologies, including blue hydrogen with carbon capture and storage (CCS). They operated within the energy and industrial sectors.

Hyzon Motors: Specialized in manufacturing hydrogen fuel cell-powered commercial vehicles, integrating blue hydrogen as a fuel source. This placed them in the transportation sector, specifically in zero-emission vehicle technologies.

H2U (Hydrogen Utility): Focused on hydrogen production and storage, specifically developing large-scale blue hydrogen projects with CCS. They were involved in the energy production and storage sectors.

ZeroAvia: A startup focused on hydrogen-electric aviation solutions, exploring the use of blue hydrogen to reduce carbon emissions in the aviation industry. They operated within the aerospace and aviation sectors, focusing on sustainable aviation fuels.

Nel ASA: Nel ASA plays a significant role in advancing green hydrogen solutions, including projects integrating renewable energy sources for sustainable hydrogen production. They contribute to the energy and industrial sectors with a focus on clean energy solutions.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Technology Intelligence

- Market Research

- Patent Landscape

- Technology gap analysis

- Design Patent Search

- Portfolio Analysis

- Freedom to operate

- Bio Sequence Search

- Innovation pipeline identification

- Chemical Structure Search

- Patent Invalidity Search

- Manufacturers Search/ Supplier search

- Patent Licensing Services

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.