Note: The free primer on Biofuel Technology Innovation & Market Research can be requested from here.

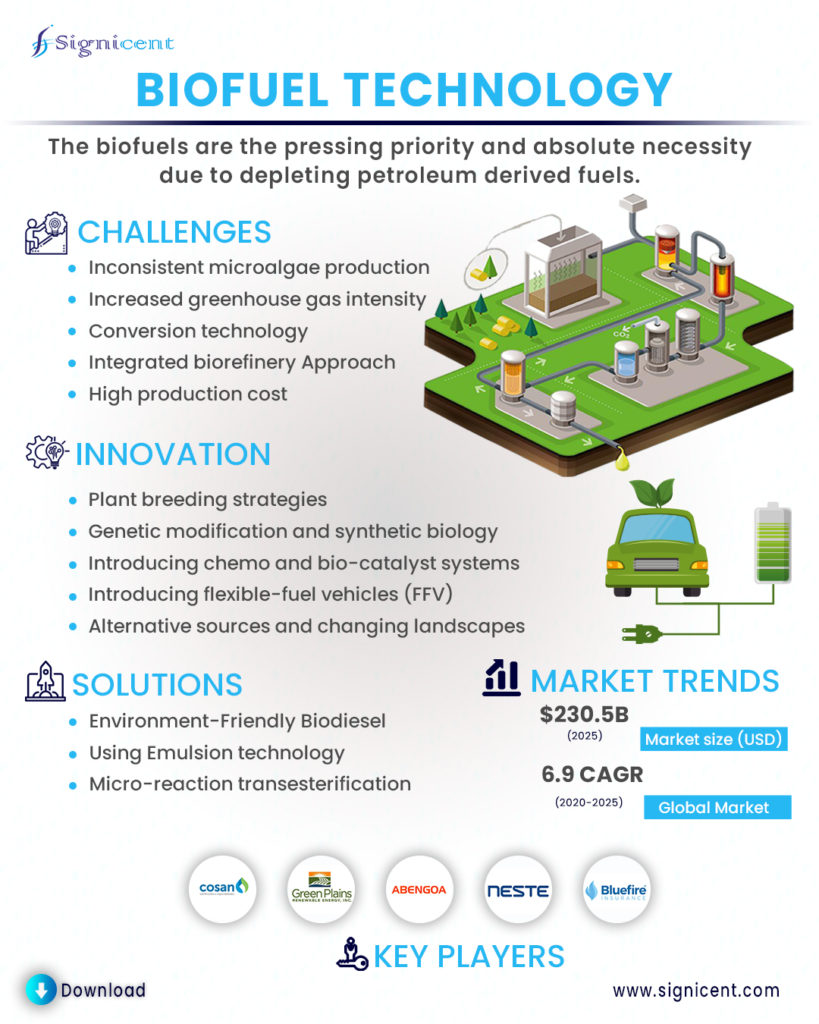

The biofuels are the pressing priority and absolute necessity due to depleting petroleum derived fuels. Moreover, the environmental concerns have propelled essentially the need to focus on biofuels. Biofuels can prove to be the savior. Biofuels have been proclaimed as the solution to energy production problem as well as to greenhouse gas emissions. Biofuels are increasingly providing an alternative to traditionally used and highly polluting fossil fuels.

Innovative methods are incorporated in producing biofuels that are extremely cost efficient as compared to traditional methods. This technical article will summaries most of the technologies, process and innovations happening to find alternative to petroleum derived fuels.

Renowned companies as well as startups are more concerned about how they can replace about 1% of the annual petrol consumption by using biofuels. Few have successfully saved around 50,000 tons of CO2 per year. Let us dwell deeper to get industry insights on biofuels.

Biofuels

Biofuel Technology Innovation is happening at very fast pace. It is true for biofuels too. Therefore, new methods are taken into consideration which are as follows:

- Plant breeding strategies, genetic modification and synthetic biology.

- Introducing chemo- and bio-catalyst systems

- Introducing flexible-fuel vehicles (FFV)

- Alternative sources and changing landscapes.

Challenges Associated with Biofuels

To understand the industry challenges, we thoroughly investigated thousands of scientific literatures, patent literatures, and recent biofuel technology innovation and inventions to figure out the major problem areas of concern. We came across the following challenges that are most commonly faced.

- Wastewater treatment from biodiesel production: Water is potentially a major limiting factor in algal growth. Treatment of water from biodiesel production still poses a challenge to the industries.

- High production cost: Recent estimates of biofuel production costs show that the biofuels are two to three times more expensive than petroleum fuels on an energy equivalent basis.

- Insufficient production of biofuel compounds: Biofuel compounds including lipid, carbohydrate, and hydrogen which are not sufficiently produced by microalgae under normal conditions.

- Inconsistent microalgae production: Inconsistent industrial-scale microalgae production is a major issue. Therefore, it leads to high harvesting cost, energy consumption for the production of biofuel from microalgae.

- Increased greenhouse gas intensity: Production of biofuels generally lead to the increased level of greenhouse gases in the atmosphere.

- Conversion technology and integrated biorefinery Approach: Conversion of biomass into value added products with maximum energy and material recovery is time consuming.

It is rightly said that once we understand the pain point, we are half way through. Now as we know the challenges, we will look for best possible solutions and innovations in Biofuel technology. And you will be amazed to read about them, keep reading.

Technology Innovation in Biofuel Production

Biofuel production can be enhanced by specifically making modifications and adding innovations to either technology involved or to the process that is involved in the production. Also, involving latest & advanced equipment for the production of biofuels has shown overwhelming results.

- Visionary Fiber Technologies (US): Fiber Reactor Technology for increased surface area. Reduced FFA content of distillers’ corn oil (DCO) from 15 percent to less than 0.5 percent. Surface area is critical for fast, complete chemical reactions.

- Si Group (US): Antioxidant stabilizers for Biodiesels. In this process no catalyst, process or feedstock is used. All fuel types are susceptible to oxidation. Ethanox antioxidants are designed to meet and exceed this challenge. Antioxidants act on the fuel stability, causing stabilization in the fuel.

- Celtic Renewables (Scotland): Low carbon green bioeconomy from biological waste and residues. Six purpose-built 130,000 liters fermentation vessels in biorefineries. Expected to process around 50,000 tons of residues each year from the whisky industry.

- Bdi Bio Diesel (Austria): Multi feedstock technology. Using 100% waste oils and fats for biodiesel production. Fully continuous process. No settling processes. Glycerin is also produced in the same line.

- Crown Iron Works (US): They are working on biodiesel process technology. Advanced Catalyst Reduction and Economization (ACRE) allows biodiesel processing plants to run at the lowest operating cost and highest efficiency. Thus, it is energy-efficient, lowers steam and energy costs for biodiesel producers

- Department of Chemistry, Thaksin University (Thailand): The department is working on cost efficient process for biofuel production from coconut meal & yeast. The highest yield was obtained from dry processing.

- Austrocel Hallein Gmbh (Austria) : They are producing bioethanol from wood sugars with higher yield. The bioethanol is produced by fermenting and distilling wood sugar from the viscose pulp mill.

- Minnesota Soybean Research & Promotion Council (US): Electricity & Liquid plasma is used to produce biodiesel. It is far less expensive than traditional methods. The process has the potential to reduce energy consumption and the cost of biodiesel production. It is able to use electricity, hence can be powered by wind or solar generations.

- Khulna University Of Engineering & Technology (Bangladesh): It is a low-cost technological approach with significant quality improvement of wastewater after microalgae cultivation. Hybrid Anaerobic Baffled Reactor and Photobioreactor System. HABR is capable of removing most of the organic and solid (>90% COD and TSS removal) from wastewater. It produced a healthy feedstock for microalgae cultivation in PBRs for biofuels production.

If you want to know more about the upcoming Biofuel Technology Innovation, reach out to us. Signicent can assist you with a vast requirement subset. Be it Technology Landscape, White space analysis, Technology scouting or Market research.

Alternatives to Biofuel Production

Some of the alternative sources for biofuel production can be categorized into –

- Plant Based: Duckweed, Wheat/Rice/ Barley/ Soybean/Corn, Cactus, Miscanthus, Hemp Stalk, Jatropha, Calophyllum, Sweet sorghum, Halophytes, Conifers.

For instance, Genetic improvement of miscanthus for biomass production (Under study (2019-10-24). Produce and process duckweed into bioethanol (In progress

(2019-03-07). Biofuel from hemp (Planning (2020-05-27). - Microbe Based: Fungi, Yeast, Algae, Microalgae, Probiotic bacteria.

For instance, Fungi as an excellent source of biofuels (In Progress (2019-04-25). Microalgae for biofuel production (In Progress (2020-01-24). Algae-derived fuel in the long-term (In Progress (2020-01-28). - Waste Derived: Coconut shell, Tropical waste, Waste vegetable oils, Plastic, Whiskey residue, Mill wastewater, Waste animal fats, Non-edible waste seeds

For instance, Production of the biodiesel from Waste vegetable oils (Established). Liquid fuel produced from plastics (Concept (2020-08-04).

Technology Scouting

- In palm oil milling, the product gets stick to the surfaces of the drier and to agglomerate. Thereby, decreasing the efficiency of the drier, extending the drying time and, possibly, leading to the breakdown of the drier

- Efficiency and exhaust emission characteristics (NOx emissions) in unmodified diesel engines is a major shortcoming.

- Processes for recovering oil from a fermentation product can sacrifice oil quality. The presence of a high level of free fatty acids can hamper the production of end products.

- Domestic biodiesel production process is a two-step reaction. The ester exchange reaction is heterogeneous, the reaction time is long, the conversion rate is low, and the energy consumption is high.

- The main bottleneck is the pretreatment referring to the expensive of cooking or otherwise softening the plant material so the sugars can be extracted and converted

Solutions

Post comprehensive analysis of publicly and commercially available information, we came across the following viable, innovative, and possibly the finest solutions to overcome these problems:

WO2020141967A1(2020-07-09) PALMITE PROCESS ENG SDN BHD [MY]

Environment- friendly and cost-effective method for treating palm oil mill effluent. Reduction in the moisture content of untreated or partially treated palm oil mill effluent using an evaporation system, followed by mixing with one or more bulking materials such as empty fruit bunches or palm fruit fiber, to form mixed biomass significantly reduced moisture content that is used either as a biofuel or as a biofertilizer.

Environment-Friendly Biodiesel/Diesel Blends (2020-05-31)

Investigated for fuel characteristics, engine performance with exhaust emission compared to diesel. Unburned hydrocarbon, carbon monoxide and smoke emissions improved with third-generation fuels (MB10, MB20) in comparison to base diesel fuel and second-generation fuels. Microalgae-biodiesel blends are a cleaner fuel for diesel engines than jatropha and polanga biodiesel, with a slight penalty in performance and emission characteristics of the engine.

US20200165642A1 (2020-05-28) (POET RES INC) [US]

The use of emulsion technology means for particle size reduction can be employed to increase surface area of plant material while raising the effectiveness of flowing the liquefied media. In order to increase the utility of the corn oil, an esterase such as a lipase can be added directly to the fermentation to facilitate chemical modification of the corn oil to give it unique properties

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

CN111411024A (2020-07-14) (Zhejiang Jiaao Environmental Protection Technology Co., Ltd.)

A device for producing biodiesel by micro-reaction transesterification, which has the advantages of simple integral structure, short reaction time, high conversion rate and high production efficiency.

New process could reduce cost of biofuel production from plant waste (2020-01-15) (Rutgers University)

Reduce the cost of producing biofuels such ethanol from plant waste. The process, which features an ammonia-salt based solvent that quickly turns plant fibers into sugars needed to make ethanol, works effectively at near-room temperature, extract over 80% of the lignin in plant waste. Reduce the cost of biofuels production.

Efficient hydrolysis of raw starch and ethanol fermentation: a novel raw starch-digesting glucoamylase from Penicillium oxalicum (2016-10-18)(Guangxi University)

A novel raw starch-digesting glucoamylase from P. oxalicum, with high enzymatic activity. Its efficient hydrolysis of raw starches and its high efficiency during the direct conversion of raw corn and cassava flours via simultaneous saccharification and fermentation to ethanol. Efficient hydrolysis of raw starch under low temperature would save energy and be more cost-effective.

Biofuel Technology Innovation: Key Collaborations for Biofuel Production

- Clariant, Switzerland (1995), has joined forces with Ineratec Germany (1999) in the challenge for a greener future in 2020. Clariant will provide its extensive catalysis expertise andbroad portfolio of syngas conditioning and upgrading catalyststo support Ineratec’s groundbreaking gas-to-liquid technology.

- Sekab E-technology, Swedish (1985)and Praj Industries, India (1983) have signed a collaboration agreement geared towards the production of sustainable biofuels. Praj industries is aiming to scale up, integrate and optimize the CelluAPP technology platform. The CelluAPP being the latest in coniferous residue conversion into biofuels, green chemicals and bio-based materials (sawdust from softwood).

- Synthetic Genomics, California based (2005) having partnered with ExxonMobil Texas based (1999) to work towards producing biofuel from algae at an unprecedented scale in 2017.

Acquired by SK Capital Partners US based (2007), focused on specialty materials, chemicals and pharmaceuticals sectors and combined with Addivant US based (2005), in 2018. The new SI Group US based (2005), developer & manufacturer of additives & chemical intermediates brings more than 100 years of excellence in manufacturing intelligent expansion and global security of supply. All fuel types are susceptible to oxidation. Ethanox antioxidants are designed to meet and exceed this challenge.

According to Forbes report on fossil fuels there has been a global surge in carbon dioxide emission by 50%. This calls for an action, for exploring the recent advancements made in the biofuel industry. You may contact Signicent for a customized research as per your current need.

Market Research on Biofuels

Global Biofuels Market trends are discussed below:

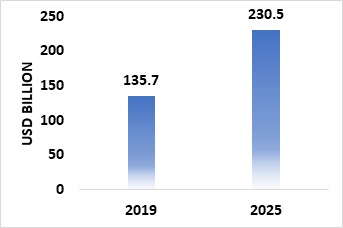

- The global biofuels market size valued, USD 135.7 billion in 2019 is expected to grow at a compound annual growth rate (CAGR) of 6.9% reaching a value of USD 230.5 billion by 2025.

- The global biodiesel market size, valued USD 35.1 billion in 2019 is expected to grow at a compound annual growth rate (CAGR) of 7.0% reaching a value of USD 49.2 billion by 2024.

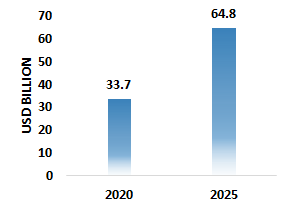

- The global bioethanol market size, valued USD 33.7 billion in 2020 is expected to grow at a compound annual growth rate (CAGR) of 14.0% reaching a value of USD 64.8 billion by 2025.

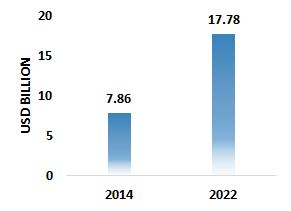

- The global biobutanol market size, valued USD 7.86 billion in 2014 is expected to reach a value of USD 17.78 billion by 2022 and will gain a compound annual growth rate (CAGR) of 6.9% during the period 2020 to 2026.

Technology Commercialization of Innovation in Biofuel

- NESTE, Finland based, is one of the world’s largest producers of renewable diesel.

- ABENGOA, Spain based, is specialized in the development of new technologies that produce biofuels. It promotes sustainability of raw materials.

- BLUEFIRE, California based, deploys ‘concentrated acid hydrolysis technology process’ for the conversion of cellulosic waste materials to ethanol, and other alternatives to petroleum derived fuels.

- COSAN, Brazil based, is a Brazilian conglomerate producer of bioethanol, sugar and energy.

- GREEN PLAINS, US based, is a vertically integrated ethanol producer which sells its processing residue (corn oil) to biodiesel manufacturers.

- NOVOZYMES, US based, is a World leader in biological solutions like alpha amylases which increase the starch & corn ethanol yield and optimization of the output.

Regulatory Authorities

Start-ups innovation in Biofuel Technology

- MANT BIOFUEL (US), founded in 2014, use algae to make cost competitive renewable fuel by cheaply farming algae.

- CELTIC RENEWABLES (SCOTLAND), founded in 2011, is the first company to produce biofuel from the by-products of the scotch whisky industry.

- BIOFUEL EVOLUTION (ENGLAND), founded in 2016, converts mixed food and agricultural waste into clean, localized and decentralized bioenergy.

- INNOLTEK (CANADA), founded in 2010, manufactures and markets renewable fuels and its biodiesel is made from animal fats and non-edible by products from food industry.