The product life-cycle management report will explore emerging, novel, and innovative technologies such as Decision Tree Based Learning, SVM, MLP etc. The report also sheds light on the challenges of the industry, innovation in the product life-cycle management, future trends, market research, start-ups, and major players of the industry.

Product Life – Cycle Management report demonstrates Signicent’s analysis to determine emerging techniques in the area of Predictive Maintenance using Artificial Intelligence.

All machines are prone to run to failure, but one can minimize its consequences. A sudden coffee maker breakdown can cause an uneasy morning. Similarly, an unexpected fault in a power plant can leave thousands of people in total darkness for hours and cause a multimillion-dollar loss, simultaneously.

The average cost of unplanned downtime in energy, manufacturing, transportation, and other industries runs at $250,000 per hour or $2 million per working day. To prevent expensive outages from happening and alleviate the damage caused by breakdowns, companies need an efficient maintenance policy.

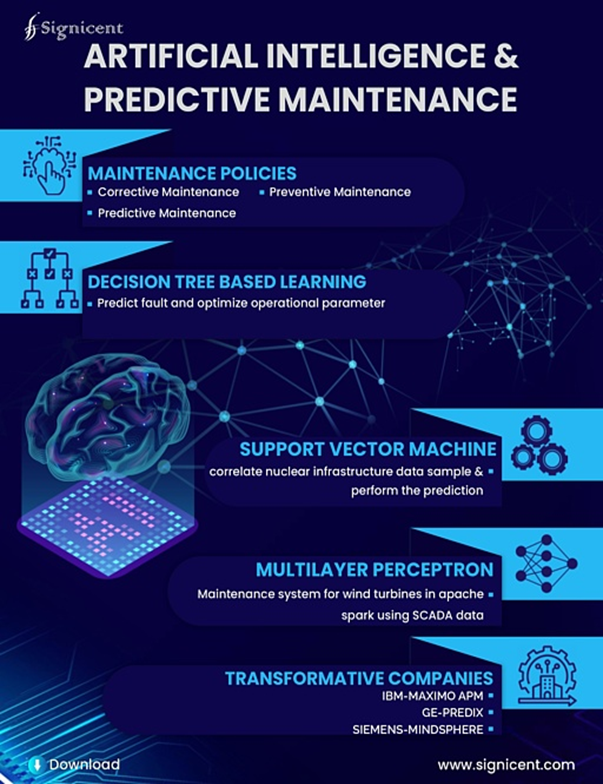

There are three major types of maintenance policies a company can stick to:

- Corrective Maintenance

- Preventive Maintenance

- Predictive Maintenance

Corrective and Preventive Maintenance have various drawbacks including high repair costs, safety risks, increased labor intensity, a potentially greater threat to machines. Therefore, with the onset of Industrial Revolution 4.0, many companies have started to emphasize adopting predictive maintenance using various Artificial Intelligence and Machine Learning techniques.

Emerging Technologies in Product Life Cycle Management

This section of the product life cycle management report sheds light on futuristic technologies. These technological advancements will majorly utilize AI that can help in the early detection of maintenance requirements.

Decision Tree Based Learning

This reference describes a monitoring system for data collection in an industrial environment. The system includes a machine learning circuit that may utilize a decision tree-based learning technique to predict faults and optimize operational parameters from the received output data reducing cost and time.

Decision Tree Model and Logistic-Regression Layer

This reference describes a fault diagnosis method for high-speed rail traveling equipment. The method includes a decision tree model for preliminary bearing fault diagnosis and a Logistic-regression layer for fault classification. This reduces repair costs and prolongs the life of the equipment.

Support vector machine (SVM)

This paper presents a novel approach to correlate nuclear infrastructure data samples where the density of probability is very low. Support vector machine and logistic regression algorithms will be used to perform the prediction. As per the literature review, support vector machines provide better performance metrics.

Tree-based classification models

In this section of the artificial Intelligence and Predictive report, Gradient Boosting, Random Forest, and Extreme Gradient Boosting models have been discussed.

In this Predicted failures probabilities are calculated through tree-based classification models (Gradient Boosting, Random Forest, and Extreme Gradient Boosting) and calculated as the temporal evolution of event data. This is achieved by applying temporal feature engineering techniques and training an ensemble of classification algorithms to predict the remaining Useful Lifetime (RUL) of woodworking machines.

Decision Tree Based Learning (Rf model)

The performance of RF, FFNN, and LR models has been evaluated for the classification of oil analysis data from gearboxes. RF outperformed the other classification models for these labels by achieving high recall and high precision

Multilayer Perceptron (MLP)

This article explores how to implement a predictive maintenance system for wind turbines in Apache Spark using SCADA data applying various algorithms. It is found that the MLP produces the most promising model for predicting failures on the given data set and that stacking multiple MLP models is a good way of producing a model with lower variance than the individual base models.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Key Companies & Products

IBM-MAXIMO APM: IBM® Maximo® APM – Predictive Maintenance Insights, helps managers predict the likelihood of future failures and determine asset failure factors that could impact plant or business operations.

SIEMENS-MINDSPHERE: MindSphere – our cloud-based IoT operating system – analyses real-time digital data streams from equipment and alerts manufacturers to impending faults that humans can’t see.

GE-PREDIX: GE’s Predix-based APM software application uses advanced predictive analytics to analyze data, detect and diagnose equipment problems before they occur, increasing asset reliability and availability while reducing operations and maintenance costs.

SAP: Keep assets up and running by using sensor data to predict equipment malfunctions and plan maintenance schedules.

Technology Scouting: Product Life Cycle Management Report

This section of the product Life-Cycle Management Report shares information on startups to collaborate with to expand the business.

Solid State AI provides solutions that enable companies to optimize their production tasks and significantly reduce asset downtime using predictive maintenance.

Acerta used machine learning to uncover actionable insights from vehicles and locate the earliest indicators of future product failures.

Infinite Devices (US) uses AI to facilitate the implementation of real-time data and enables predictive maintenance, thereby reducing downtime and lowering costs.

Credence Robotics (India) develops the Alphonso Predictive Maintenance System to help determine the condition of in-service equipment in order to estimate when maintenance should be performed.

Juconn (Germany) develops complete IoT solutions for both condition monitoring as well as predictive maintenance.

The usage of Predictive Maintenance is not limited only to the Manufacturing and Automotive industries but is also used in the nuclear and aviation industry. Some of the emerging machine learning models used are Support vector machine (SVM), Tree-based classification models (Gradient Boosting, Random Forest, and Extreme Gradient Boosting), and Multilayer Perceptron (MLP) due to low cost and time.

In addition to IBM, other large corporations such as Siemens, General Electric, Microsoft, and SAP are already using various machine learning models to determine the condition of their in-service equipment to avoid unexpected failure and reduce costs.

Universities & Startups: Product Life Cycle Management Report

Universities such as the University of Houston (US), Accenture Digital (ITALY), University of the Witwatersrand (South Africa), University of Witwatersrand (South Africa) are also active in this area.

Many OEMs prefer to work with smaller vendors for various reasons (e.g., cost, data privacy, and flexibility). Solid State AI (Canada), Acerta (Canada), Infinite Devices (US), Credence Robotics (India), Juconn (Germany) are some startups providing their services in this area.